Electronic Manufacturing Services

Electronic Manufacturing Services (EMS) encompass a wide range of processes essential for the production of electronic products.

Understanding Electronic Manufacturing Services

At Sun Electro Devices, we specialize in providing top-tier Electronic Manufacturing Services (EMS) that help businesses bring their ideas to life. With a focus on cost-efficiency, strict quality assurance, and cutting-edge technology, our EMS solutions cater to a wide range of industries, ensuring that every product is manufactured with precision and reliability. Whether you need rapid prototyping, full-system assembly, or aftermarket services, we are committed to driving your success.

Advanced Facilities

Our automated production lines and cutting-edge equipment ensure efficient, high-quality manufacturing processes.

Experienced Engineers

Our team of engineers has decades of experience in the field, providing expert guidance at every stage of your project.

Strict Quality Control

We adhere to the highest standards in the industry, ensuring that every product undergoes thorough testing and inspection.

Customer Service

From the initial consultation to post-production support, we are dedicated to offering responsive, transparent service to meet your unique needs.

Our Capabilities

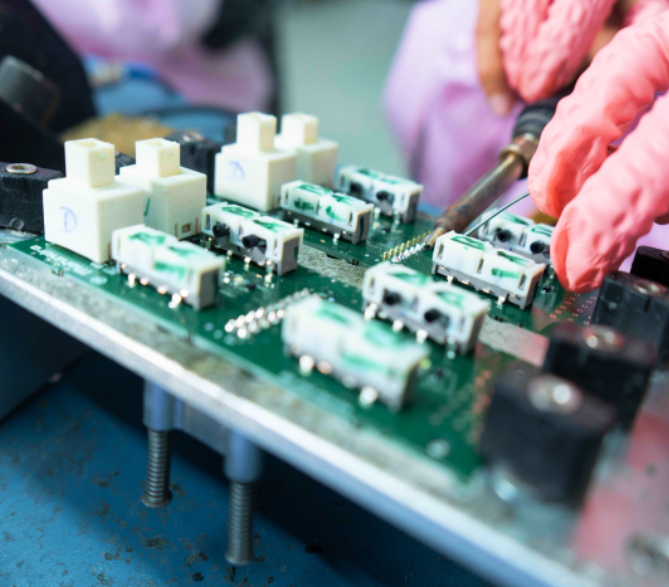

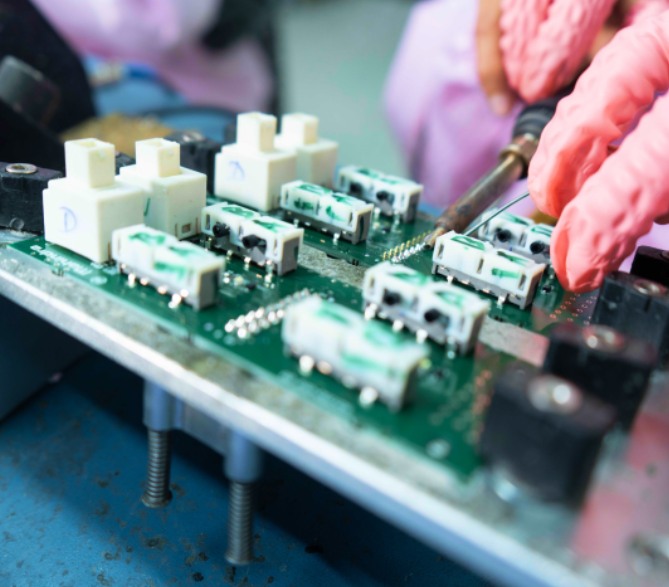

PCB Assembly

We offer both Surface-Mount Technology (SMT) and Through-Hole Technology for PCB assembly, ensuring flexibility and precision in component placement.

Prototyping

Our rapid prototyping services allow businesses to bring their ideas to life quickly, helping you test and refine designs before full-scale production.

Supply Chain Management

We handle all aspects of component sourcing and supply chain management, ensuring that your production process is seamless and efficient.

Testing and Quality Assurance

Our testing processes include in-circuit testing (ICT), functional testing, and environmental stress testing to guarantee the reliability of your products.

Aftermarket Services

We provide comprehensive aftermarket services, including repair, refurbishment, and end-of-life management, ensuring the longevity and sustainability of your products.

Our Process

Our EMS process is designed for maximum efficiency, quality, and speed

1

Consultation

We start with a detailed consultation to understand your project needs and goals.

2

Design and Prototyping

Our team develops prototypes to ensure your design is optimized for full-scale production.

3

Component Sourcing

We handle the procurement of high-quality components through our established supply chain.

4

Manufacturing

Our automated lines and skilled technicians handle every aspect of the production process, from PCB assembly to final assembly.

5

Testing and QC

Every product undergoes rigorous testing to ensure it meets your specifications and industry standards.

6

Final Delivery

Once tested and approved, your product is shipped to you, ready for market.

Where we make an impact.

At Sun Electro Devices, we’re proud to support a wide range of industries with our reliable and innovative solutions

Automotive

Innovative electronic systems improve safety, efficiency, & performance, shaping the future of transportation.

Energy & Power

We support cleaner, more efficient energy systems with our specialized manufacturing.

Defence

Our high-quality products play a crucial role in defense technology, delivering performance you can trust.

Consumer Electronics

From gadgets to home appliances, our solutions bring modern convenience to everyday life.

Industrial Equipment

We provide tough, long-lasting parts that keep factories and machines running smoothly.

Healthcare

Our components power life-saving medical devices, ensuring accuracy and reliability where it’s needed most.

Frequently asked

questions

EMS, Wiring Harness Manufacturing and Injection Molding.

How can Sun Electro Devices help reduce manufacturing costs?

Our efficient manufacturing processes, combined with expert project management, help businesses streamline production and reduce costs by minimizing waste and optimizing resources.

What if my product requires custom specifications?

We offer tailored manufacturing services to meet your unique product needs, whether it’s custom wiring harnesses, injection-molded parts, or full contract manufacturing. Our team works closely with you to ensure the end product aligns perfectly with your requirements.

How do you ensure quality in your products?

We have strict quality control measures in place at every step of production, from raw materials to final testing, ensuring every product meets the highest industry standards.

How can your solutions improve the performance of my products?

Our advanced electronic systems and components are engineered to enhance the performance, durability, and efficiency of your products, whether you’re in automotive, healthcare, or industrial sectors.

Do you offer support after product delivery?

Yes, we provide ongoing support after product delivery, ensuring any issues are addressed and that your product continues to perform at its best.